When you lather up in the morning, you’re likely focusing on the scent or how well the suds rinse out. You probably aren’t thinking about the complex engineering and scientific precision happening behind the scenes. At Jindao Shampoo Factory, that intricate world of shampoo manufacturing is our daily reality. We bridge the gap between a creative vision and the high-quality bottles sitting on bathroom shelves across the country.

The Art of Product Development

Every great hair care routine starts in a laboratory, not a mixing vat. Product development is the heartbeat of what we do. It begins with understanding the diverse needs of consumers—whether they are looking for volume, hydration, or scalp health.

Our team of chemists works on custom formulations that balance cleansing agents with nourishing additives. We don’t just make “soap for hair”; we engineer solutions. This involves testing pH levels to ensure the product is gentle on the skin and selecting the right essential oils or proteins to achieve specific results.

The Production Process: Precision at Scale

Once a formula is perfected, it moves to the production process. At Jindao Shampoo Factory, this is where science meets industrial efficiency.

- Water Purification: High-quality shampoo requires ultra-pure water. We use advanced filtration to remove minerals that could interfere with the formula.

- Ingredient Blending: Using industrial-scale mixers, ingredients are added in a precise sequence. Temperature control is vital here; some conditioners only integrate perfectly at specific heat levels.

- Quality Control: Before a single bottle is filled, samples are tested for viscosity, scent consistency, and shelf-life stability.

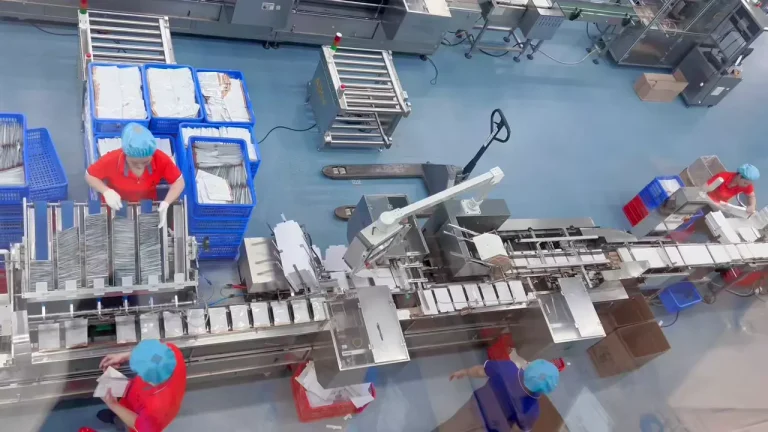

- Automated Filling: Our high-speed lines dispense the shampoo products into containers, seal them, and apply labels with surgical precision.

Custom Shampoo and Private Labeling

One of the fastest-growing sectors in personal care products is the demand for unique, branded experiences. This is where our private label shampoo services shine.

Many entrepreneurs and salon owners have a brilliant idea for a brand but lack the multi-million dollar infrastructure to build their own facility. Jindao Shampoo Factory acts as their manufacturing partner. We offer:

- Custom shampoo scents and colors tailored to a brand’s identity.

- Packaging options that stand out on retail shelves.

- Scalable production runs, allowing boutique brands to grow into household names.

Why Quality Matters in Hair Care

The “high-quality” label isn’t just marketing jargon—it’s a commitment to safety and efficacy. Using inferior surfactants can strip hair of its natural oils, leading to long-term damage. By focusing on premium ingredients and rigorous testing, we ensure that every bottle leaving our facility contributes to healthier, more beautiful hair.

The next time you enjoy that perfect lather, remember that it is the result of months of research, careful sourcing, and a dedicated team of manufacturing experts. At Jindao Shampoo Factory, we don’t just bottle liquid; we bottle confidence.

Technical Specification Sheet: Moisturizing Botanical Formula

A technical specification sheet (TSS) is a vital document in shampoo manufacturing. It serves as the blueprint for product development, ensuring that every batch produced at Jindao Shampoo Factory meets the exact standards of the custom formulations requested by our clients.

Below is a breakdown of a standard high-quality moisturizing shampoo specification.

1. Physical & Chemical Properties

These parameters ensure the product is stable, safe, and provides the desired sensory experience.

| Property | Target Specification | Method/Standard |

| Appearance | Pearlescent, viscous liquid | Visual Inspection |

| Color | Off-white to Pale Gold | Colorimeter |

| Odor | Botanical/Floral (Custom) | Sensory Analysis |

| pH Value | $5.5 – 6.5$ | pH Meter @ 25°C |

| Viscosity | $5,000 – 8,000$ cps | Brookfield Viscometer |

| Specific Gravity | $1.02 – 1.05$ | Pycnometer |

2. Ingredient Composition (INCI)

In personal care products, ingredients are listed by their International Nomenclature Cosmetic Ingredient (INCI) names. A typical high-quality moisturizing blend includes:

- Primary Surfactant: Sodium Lauroyl Methyl Isethionate (Sulfate-free cleansing agent).

- Secondary Surfactant: Cocamidopropyl Betaine (Foam booster and mildness enhancer).

- Conditioning Agents: Polyquaternium-10 and Guar Hydroxypropyltrimonium Chloride.

- Active Botanicals: Aloe Barbadensis Leaf Juice, Argania Spinosa (Argan) Kernel Oil.

- Preservative System: Phenoxyethanol and Ethylhexylglycerin (Paraben-free).

3. Microbiological Standards

To guarantee consumer safety, every private label shampoo batch must pass rigorous microbial testing.

- Total Aerobic Microbial Count (TAMC): $< 100$ CFU/g

- Total Yeast and Mold Count (TYMC): $< 10$ CFU/g

- Pathogens (E. coli, S. aureus, P. aeruginosa): Absent

4. Stability and Packaging

Before the production process reaches full scale, the formula undergoes stress testing to ensure it doesn’t separate or change color over time.

- Freeze-Thaw Stability: 3 cycles ($-10°C$ to $25°C$).

- Accelerated Aging: 12 weeks at $45°C$ (simulates 2 years of shelf life).

- Packaging Compatibility: Tested with HDPE, PET, or PCR (Post-Consumer Recycled) plastic containers to ensure no leaching or deformation.

5. Regulatory Compliance

At Jindao Shampoo Factory, we ensure all shampoo products comply with the following:

- FDA Guidelines: Compliance with the Modernization of Cosmetics Regulation Act (MoCRA).

- IFRA Standards: Fragrance safety compliance.

- Cruelty-Free: No animal testing involved in the development phase.