Choosing the right shampoo OEM factory is a comprehensive process that requires considering multiple factors to ensure the quality and market competitiveness of the final product. Here are some key steps and considerations:

I. Define Needs and Positioning

Product Characteristics and Positioning: Determine the shampoo’s efficacy (e.g., oil control, dandruff removal, hair loss prevention, nourishing, etc.). Analyze the target market and audience to understand their needs and preferences.

Budget Considerations: Set a reasonable budget range based on the brand’s development stage and financial situation.

II. Evaluate the Shampoo OEM Factory’s Qualifications and Strength

Certificates and Qualifications: Check if the shampoo OEM factory possesses the required national or industry certifications, such as ISO22716, GMPC, etc. Ensure the factory has valid operating licenses.

Production Scale and Experience: Understand the shampoo OEM factory’s production scale, capacity, and experience in the industry. Prioritize factories with extensive experience and a good reputation.

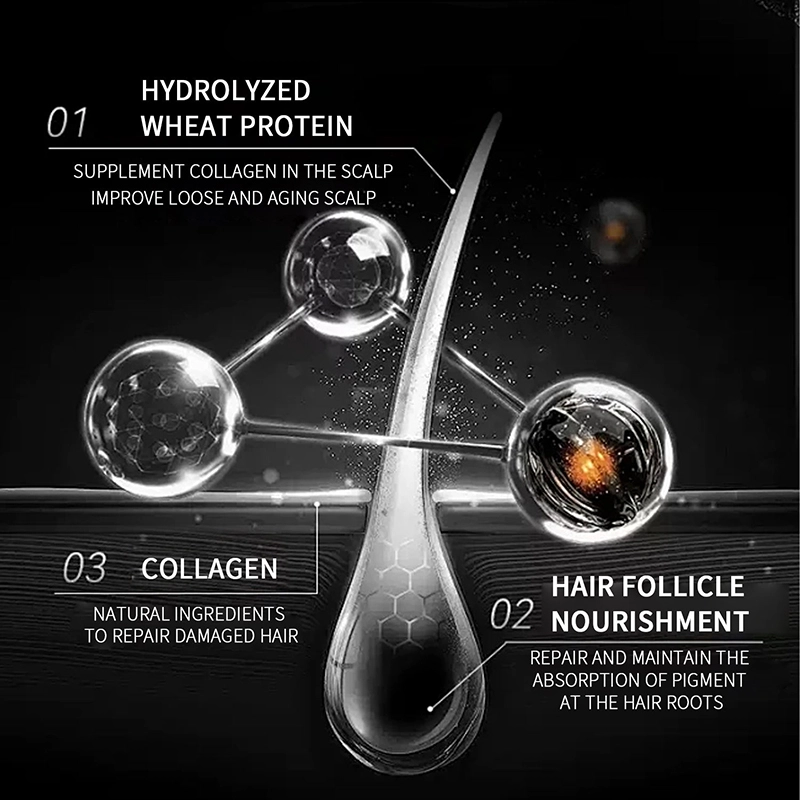

R&D Strength: Examine the shampoo OEM factory’s R&D team and research capabilities to ensure they possess innovation capabilities and technological strength.

III. Inspection of Production Equipment and Hygiene Conditions

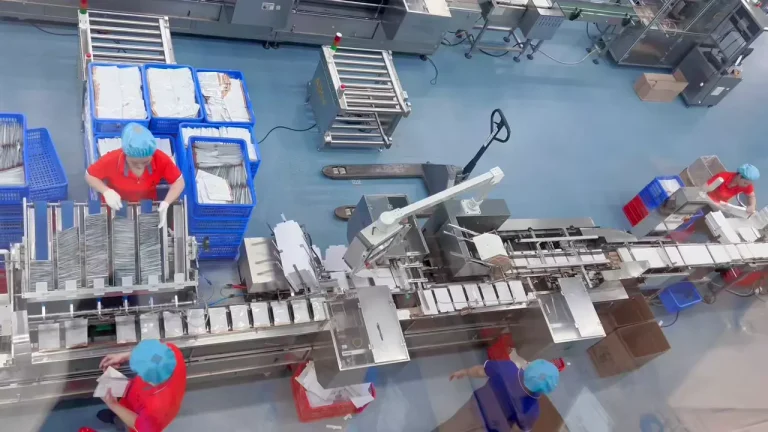

Production Equipment: Check if the shampoo OEM factory has advanced production equipment and production lines to ensure the product’s appearance and feel. Inquire about the frequency of equipment upgrades and maintenance to ensure the stability and efficiency of the production process.

Hygiene Conditions: Visit the shampoo OEM factory’s production workshop to understand its hygiene conditions and management systems. Ensure the factory has strict disinfection and cleaning procedures to prevent product contamination.

IV. Focus on Product Quality and Prototyping

Sample Testing: Request samples from the shampoo OEM factory for testing, including stability and safety tests. Ensure the samples meet national and industry standards, as well as the brand’s requirements.

Market Feedback: Conduct small-scale market testing to collect consumer feedback. Adjust product formulas and production processes based on the feedback results.

V. Consider Cost and Service

Price Comparison: Compare prices from different shampoo OEM factories to ensure you choose the factory with the best value within your budget.

After-sales service: Understand the after-sales service policies of the shampoo OEM factory, including technical support, logistics and distribution, and return and exchange processing. Choose a factory that can provide comprehensive services to ensure timely support and assistance during product production and sales.

VI. Contract Signing and Production Supervision

Contract Signing: After selecting a shampoo OEM factory, sign a detailed contract with them, clearly defining the rights and obligations of both parties. This should include clauses regarding product specifications, quantity, price, delivery time, and quality standards.

Production Supervision: Maintain communication with the shampoo OEM factory during the production process to monitor production progress and quality. If necessary, send personnel to the factory for supervision or conduct regular spot checks on product quality.

In summary, choosing a suitable shampoo OEM factory requires comprehensive consideration of multiple factors, including product characteristics and positioning, the shampoo OEM factory’s qualifications and strength, production equipment and hygiene conditions, product quality and sampling, cost and service, and contract signing and production supervision. Through careful evaluation and comparison, you can select the shampoo OEM factory that best suits your needs, laying a solid foundation for brand development.