Every morning, millions of people reach for a bottle of shampoo to start their day. While we often focus on the scent or the lather, the journey from raw ingredients to the finished product is a fascinating blend of high-tech chemistry and industrial precision. At the heart of this global industry is Jindao Shampoo Factory, a facility dedicated to the art and science of professional-grade hair care production.

The Foundation of Quality

Shampoo manufacturing is much more than simply mixing soap and water. It begins with the careful selection of raw materials. Most shampoos are composed of approximately 70-80% water, which must be purified through a multi-stage Reverse Osmosis (RO) system to ensure no minerals or impurities interfere with the formula.

The remaining ingredients include:

- Surfactants: The cleaning agents that lift oil and dirt.

- Conditioning Agents: To leave hair smooth and manageable.

- Thickeners: To provide that satisfying, rich texture.

- Fragrances and Preservatives: To ensure a pleasant experience and long-term safety.

The Blending Process

At Jindao Shampoo Factory, the manufacturing process occurs in massive, temperature-controlled stainless steel vessels. The surfactants are first combined with the purified water. This stage requires a delicate balance of heat and agitation; the mixture must be stirred at specific speeds to ensure uniformity without creating excessive foam.

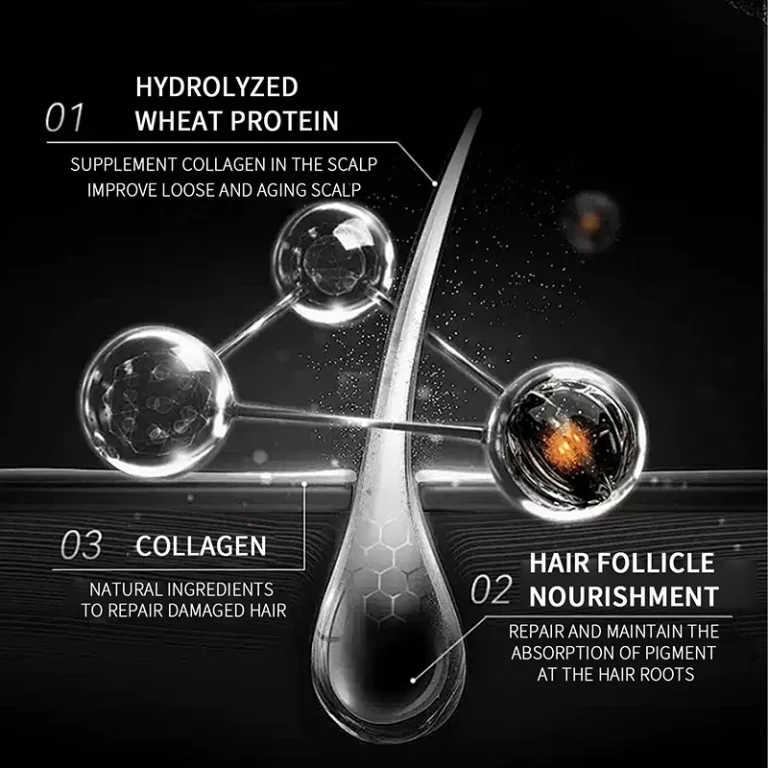

Once the base is stable, specialized “active” ingredients—such as botanical extracts, proteins, or vitamins—are integrated. The final step in the mixing phase is the “finishing,” where the pH levels are adjusted to be compatible with human skin, and the signature scent is added.

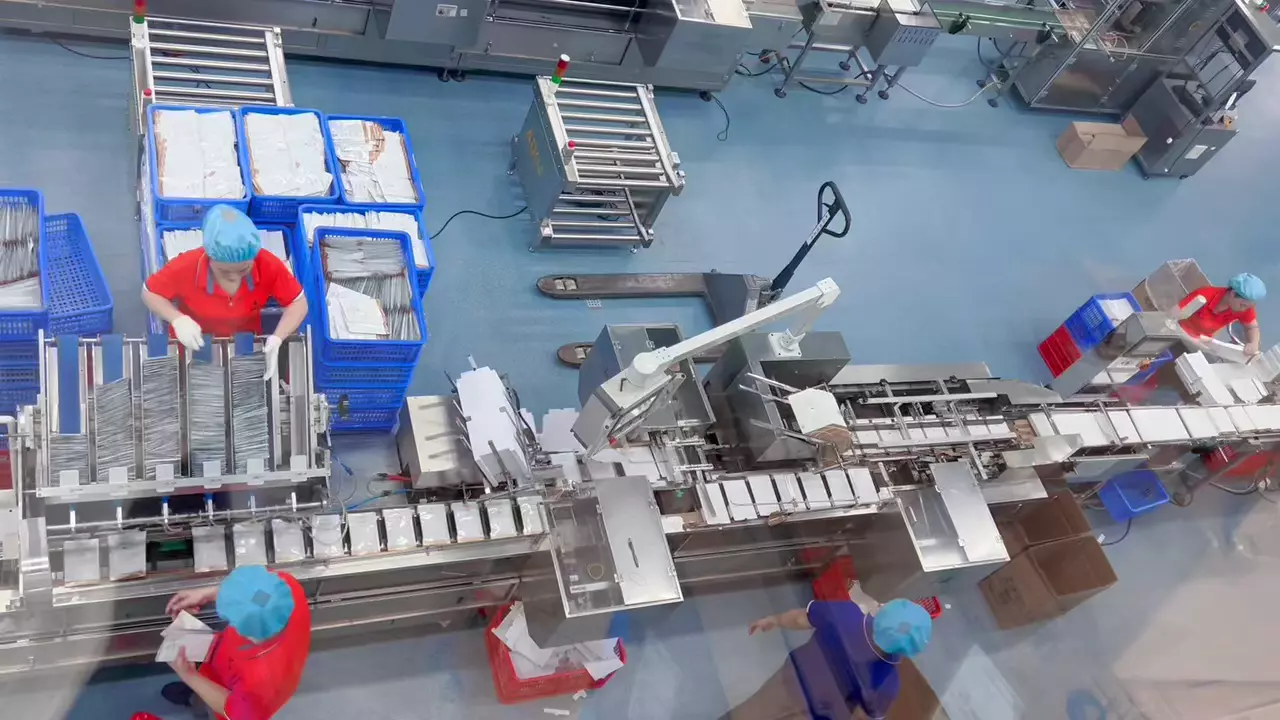

Precision Bottling and Quality Control

After a batch is approved by the lab, it moves to the high-speed automated bottling lines. This is where precision is paramount. Automated sensors ensure that every bottle is filled to the exact milliliter, while robotic arms apply caps and seals with perfect tension.

Jindao Shampoo Factory places a heavy emphasis on quality control. Every batch undergoes rigorous testing for:

- Viscosity: Does it pour correctly?

- Microbial Safety: Is it free from bacteria?

- Lather Performance: Does it produce the expected amount of foam?

Why the Factory Model Matters

For many beauty brands, partnering with an established manufacturer like Jindao Shampoo Factory is the only way to ensure consistency. By utilizing a dedicated facility, brands benefit from cGMP (Current Good Manufacturing Practices) standards, which provide the safety guarantees that modern consumers demand.

In the world of shampoo manufacturing, the goal is simple but the execution is complex: to create a product that is safe, effective, and consistently high-quality every time you pop the cap.

Would you like me to draft a technical breakdown of specific surfactant types used in modern formulas, or perhaps a guide on how to start a private-label hair care brand?

Inside a Modern Herbal Shampoo Factory

This video provides a detailed look at the automated manufacturing workflow, from ingredient dosing to final bottling, which helps visualize the industrial scale discussed in the article.