In today’s fiercely competitive daily chemical market, an emerging brand looking to quickly launch its own shampoo product often faces a practical dilemma: should it invest heavily in building its own production line, or seek a more efficient and flexible solution? For many brands aiming to rapidly expand their market share, partnering with professional shampoo manufacturers—that is, choosing OEM services—has become a proven and viable path. This collaborative model allows brands to focus their resources on core aspects such as product design, marketing, and channel development, while entrusting the complex production tasks to factories with professional capabilities and economies of scale.

So, what is shampoo OEM service? Simply put, it refers to a brand entrusting a factory with the appropriate qualifications and production capabilities to handle the entire process of shampoo production, bottling, and packaging, according to a provided formula or a jointly developed formula. The brand owns the intellectual property rights and brand ownership, while the processing plant is responsible for transforming the concept into a concrete product that meets quality standards.

What specific benefits can OEM services bring to a brand’s market expansion? We can understand this from the following aspects:

- Significantly Reduced Initial Investment and Risk: Building a factory requires substantial capital for factory buildings, equipment, production lines, and the establishment of a professional team. This is a heavy burden for startups or companies looking to test new product lines. The OEM model eliminates this huge fixed asset investment, allowing brands to start projects at a relatively low cost and use funds more flexibly for market expansion, greatly reducing the barriers and risks of starting a business and innovating products.

- Rapid Product Launch: Time is market opportunity. Professional OEM factories possess mature production lines, stable raw material supply chains, and skilled operating procedures. From confirming cooperation to product launch, the cycle is usually much shorter than building capacity in-house. This means brands can respond to market trends more quickly, seize consumer hotspots, and get new products to consumers rapidly, gaining a competitive edge in the market.

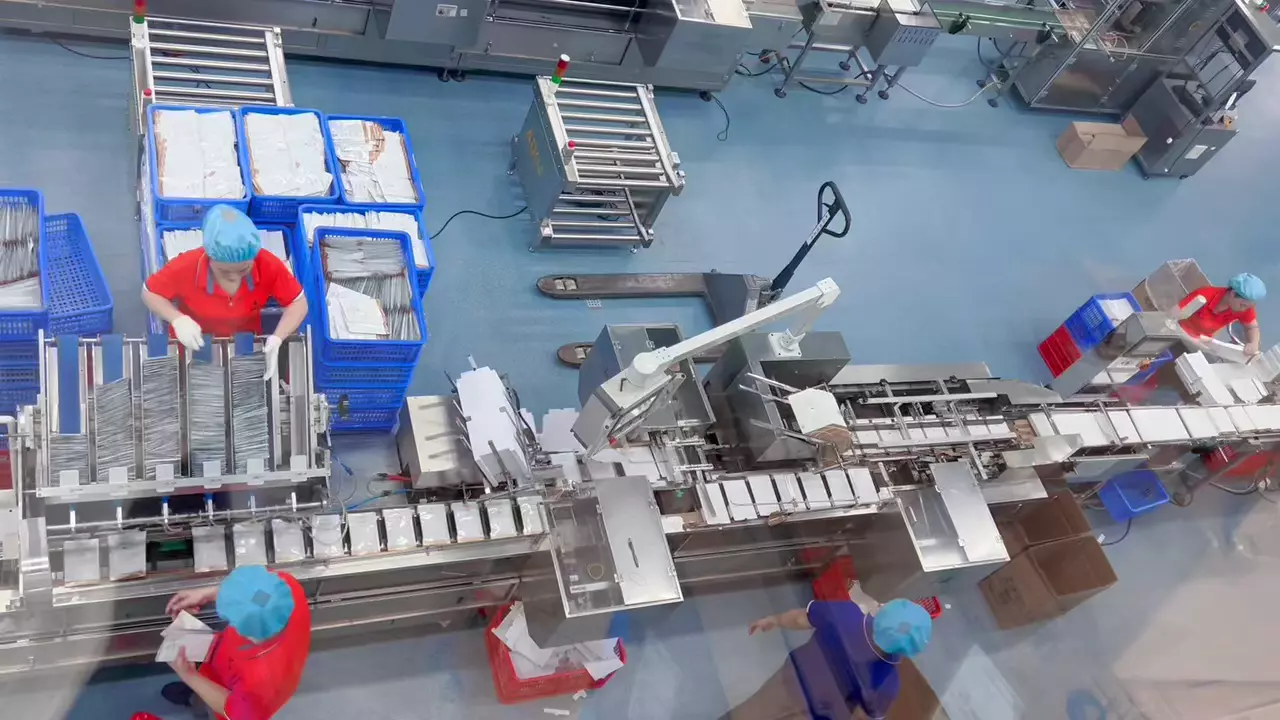

- Leveraging Professional Production Technology and Quality Systems: High-quality contract manufacturers not only provide production equipment but also professional technical support and strict quality control. Take Guangzhou Jindao Shampoo Factory, which specializes in personal care products, as an example. Such companies typically have professional R&D teams and laboratories, capable of assisting brands with formula prototyping, skin feel adjustments, and stability testing. They are familiar with industry regulations and standards, and have established comprehensive quality management systems to ensure that every bottle of shampoo produced meets relevant national requirements, ensuring stable and reliable quality. Brands can leverage their expertise to enhance the competitiveness of their products.

- Enjoying Supply Chain and Scale Advantages: Large contract manufacturers have cost advantages in raw material procurement due to their large purchasing volumes. This advantage can be partially transferred to brands, helping them optimize product cost structures. The factory’s mature production management experience also ensures stable supply capacity during peak production seasons or when order volumes are high, providing a solid foundation for the brand’s marketing and promotional activities.

- Flexible Response to Market Demand Changes: OEM models typically offer flexible minimum order quantities (MOQs), allowing brands to produce products with different effects or fragrances in small batches and multiple batches based on market feedback for market testing. Once a product becomes a bestseller, orders can be quickly increased. This flexibility allows brands to operate with a lighter load, avoiding large inventory buildups and adjusting market strategies more nimbly.

When considering partnering with an OEM manufacturer, brands naturally care about choosing a reliable partner. The following key points deserve special attention:

- Factory Qualifications and Certifications: Verify whether the factory possesses a valid production license and whether its production environment meets standards. Whether it has passed internationally or industry-recognized quality management system certifications are fundamental proof of its production compliance.

- R&D and Technical Support Capabilities: Does the factory have an independent R&D laboratory and technical team? Can it provide suggestions for formula development, upgrades, or adjustments based on the brand’s concepts? Strong R&D capabilities are the guarantee for product differentiation and efficacy.

- Production Equipment and Capacity: Visit or understand the factory’s production lines to assess their advancement, automation level, and ability to meet specific product manufacturing requirements (e.g., low-temperature formulation, homogenization emulsification). Also, evaluate whether its capacity matches the brand’s current and future market demand.

- Quality Control Process: Understand the factory’s entire quality control process, from raw material warehousing to finished product delivery. This includes whether raw material inspection, semi-finished product testing, and finished product inspection are complete and whether detailed records are kept for traceability.

- Past Cooperation Cases and Reputation: Examine the types of brands the factory has served and their past projects to understand its reputation within the industry. Successful cooperation cases are strong evidence of its strength.

For example, the Guangzhou Jindao shampoo factory, located in an industrial cluster, exemplifies the typical value of an OEM manufacturer. By integrating R&D, production, and supply chain resources, it provides solutions from concept to finished product for brands with different needs. Its operating model demonstrates how modern OEM services help brands focus on the market while systematically outsourcing specialized production tasks.

Of course, brands also need to clearly define their responsibilities when collaborating with contract manufacturers. Brands need to clearly define their product positioning, target audience, and core selling points, and maintain close communication with factories to ensure the accurate transformation of the product from concept to reality. Brands are still responsible for product registration, marketing, and sales channel development, ensuring effective coordination with the contract manufacturer’s production process.

Contract manufacturing services for shampoo are a highly specialized social division of labor and collaboration model. By combining a brand’s market acumen with a factory’s production expertise, it effectively solves the challenges of production capacity, technology, quality, and cost faced by brands, especially emerging brands, during market expansion. This model is becoming an important force driving innovation and prosperity in the daily chemical market, helping more brands enter the market more agilely and providing consumers with a wider variety of product choices. For brands aspiring to make a name for themselves in the shampoo and hair care industry, choosing a suitable contract manufacturing partner is undoubtedly a key strategic step in accelerating their market expansion.